Tanaka, Aso

We tried to replace the noise PD of the OMC trans (PD B) today.

Summary

We were able to swap the PD without moving anything in the chamber.

However, the replaced PD does not respond to the laser pointer.

Probably, the PD was broken during the can opening process.

We will prepare another PD (this time, opening the can more carefully) tomorrow.

Details

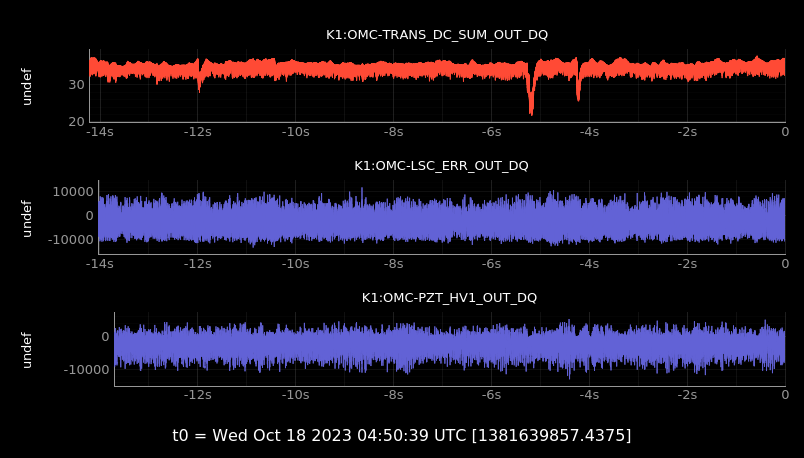

PD dark noise check before swap

As a reference, we measured the PD dark noise before doing anything.

To do this measurement, we swapped the in-air cable for the DCPD from the one running through the ceiling, which we know to cause a lot of noise, to a temporary cable on the floor.https://klog.icrr.u-tokyo.ac.jp/osl/uploads/27207_1697448867_DCPD-Noise-Before-Swap.pdf

DCPD B is clearly noisier.

DCPD pre-amp noise

We then disconnected the PDs from the in-vac pre-amplifier to check the noise of the pre-amp itself.

https://klog.icrr.u-tokyo.ac.jp/osl/uploads/27207_1697448989_DCPD-PreAmp-Noise.pdf

The references are when the PDs are connected.

The pre-amp noise is fine.

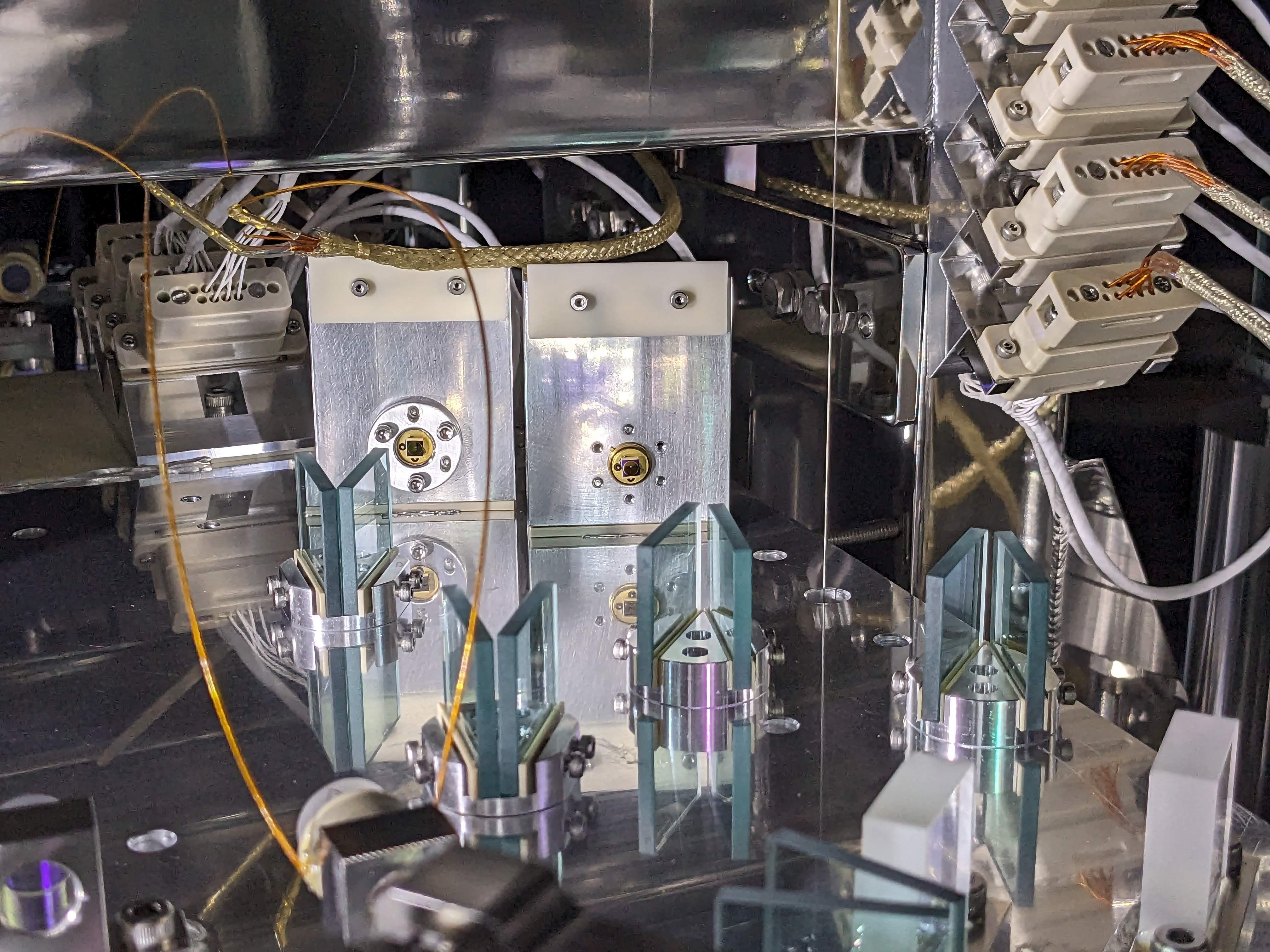

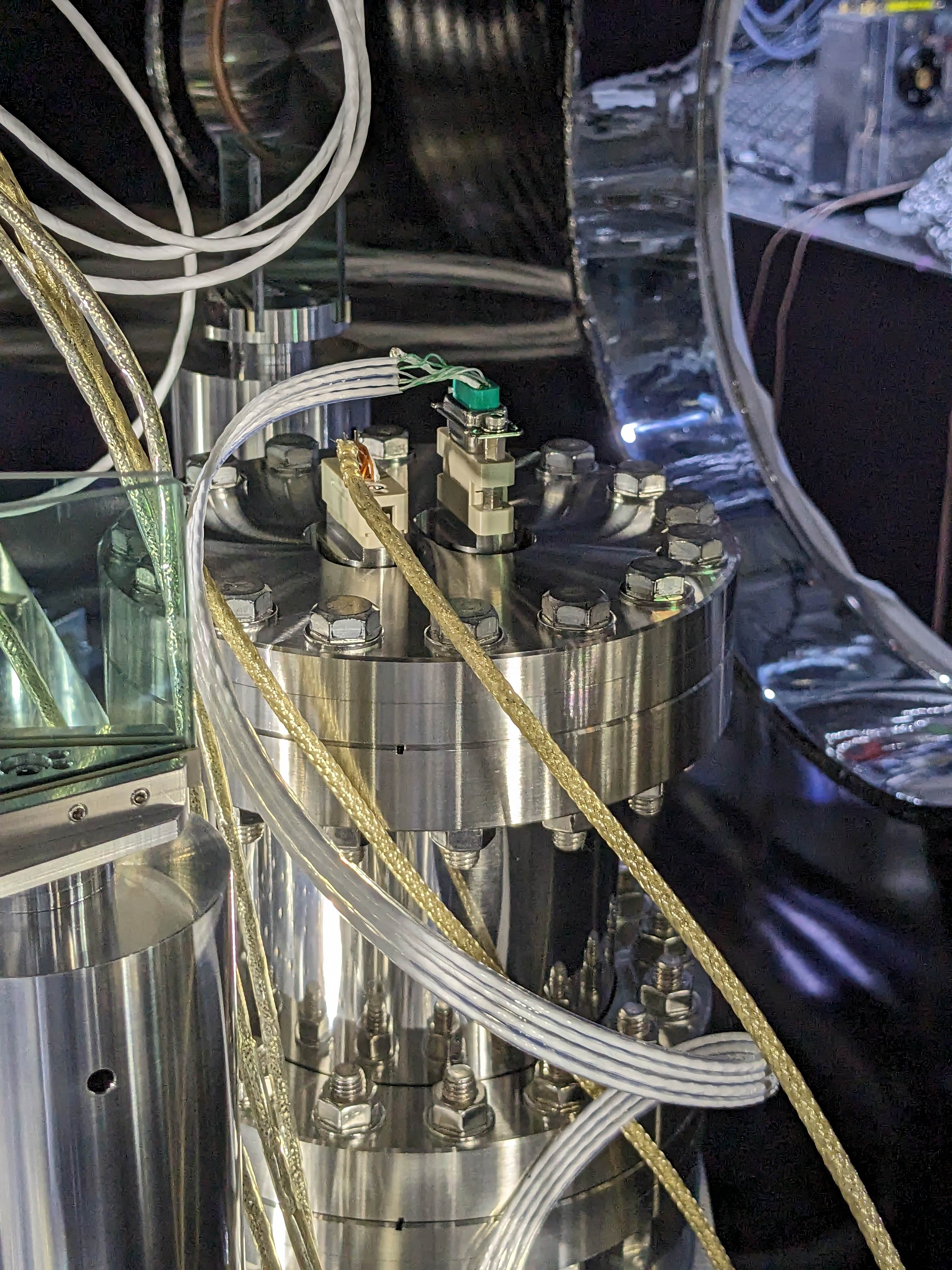

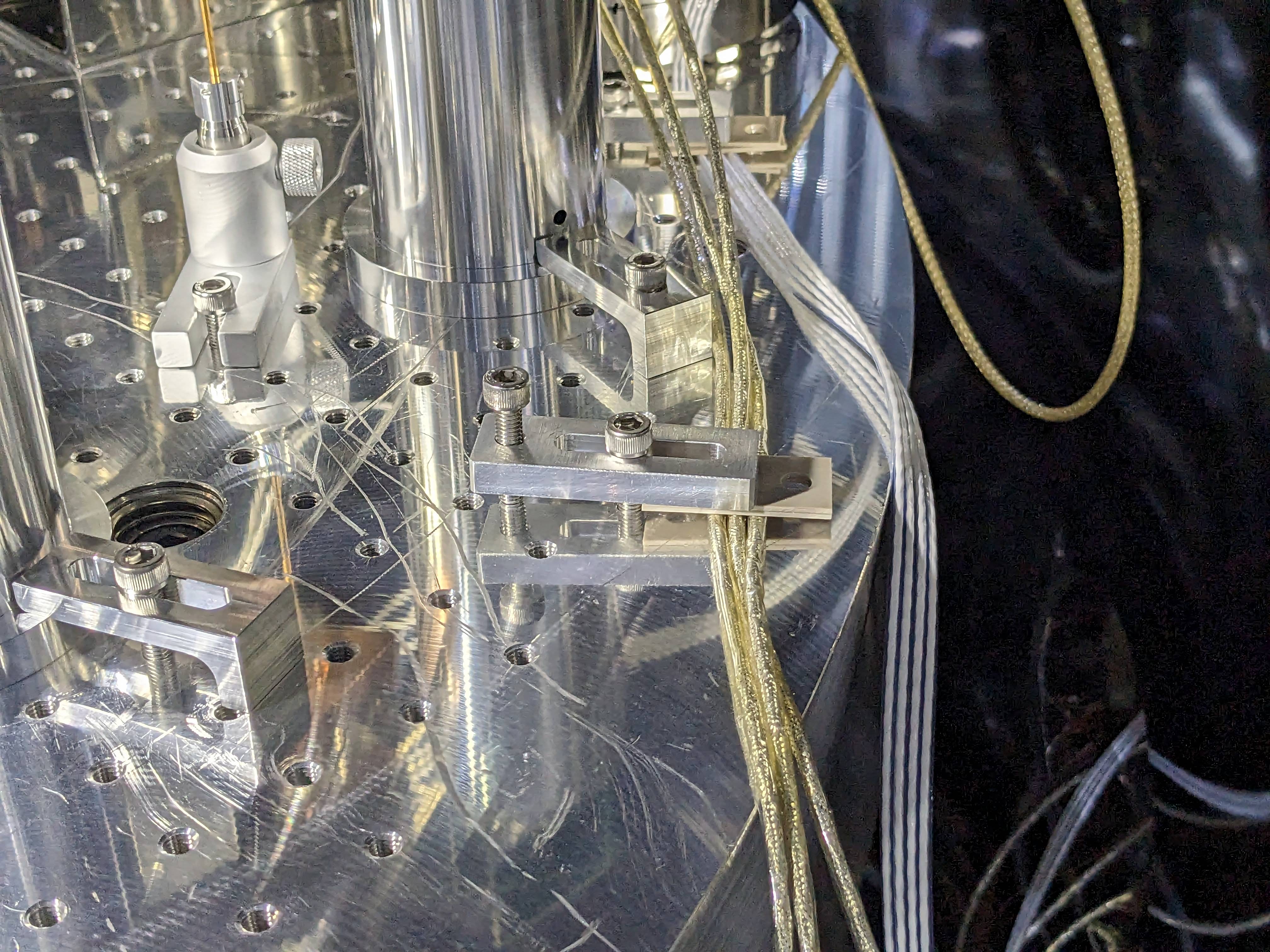

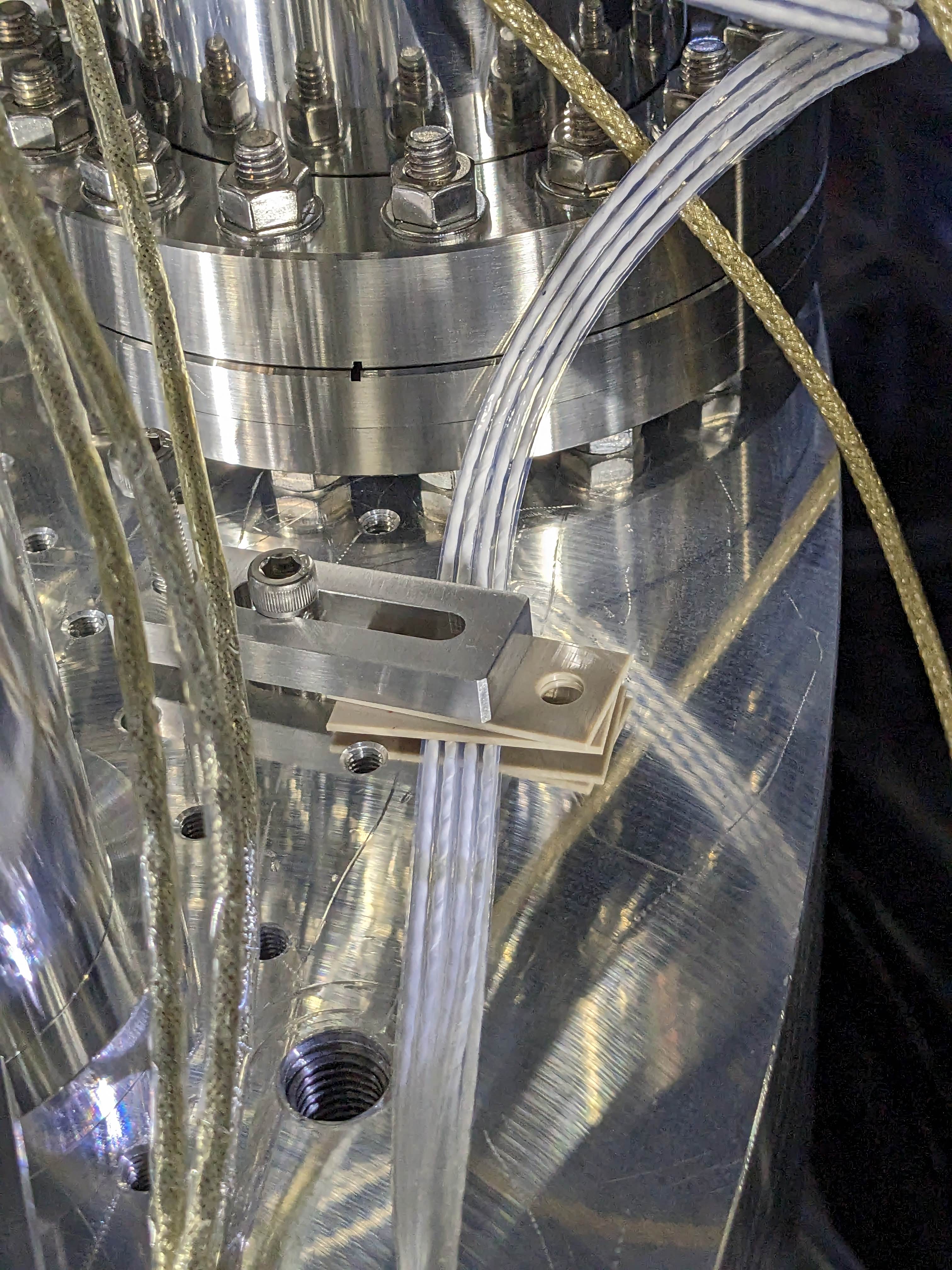

Preparation for the PD swap

- Locked the OMC bread board with 4 screws

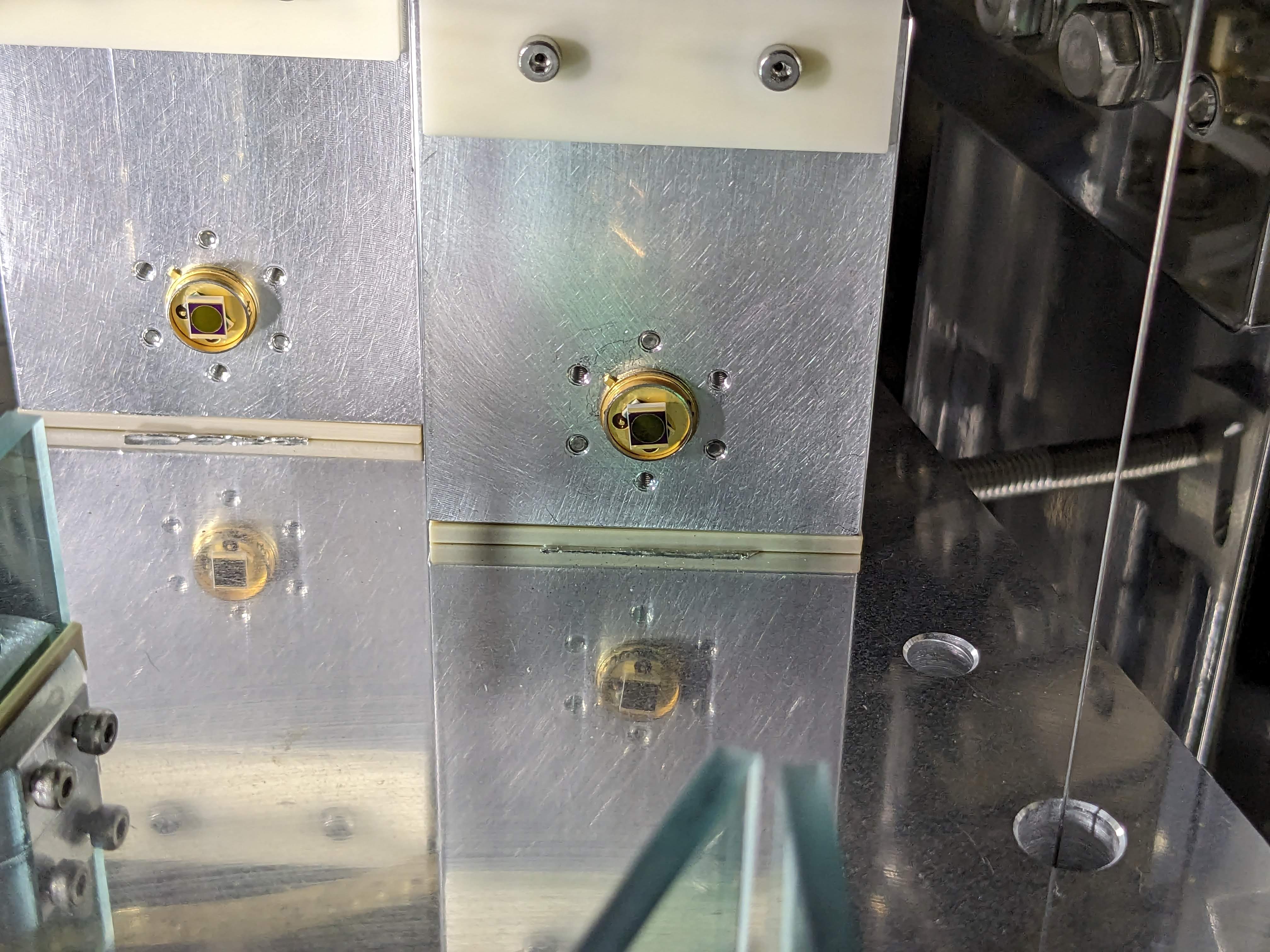

- Illuminate each PD with a laser pointer to identify which PD corresponds to B.

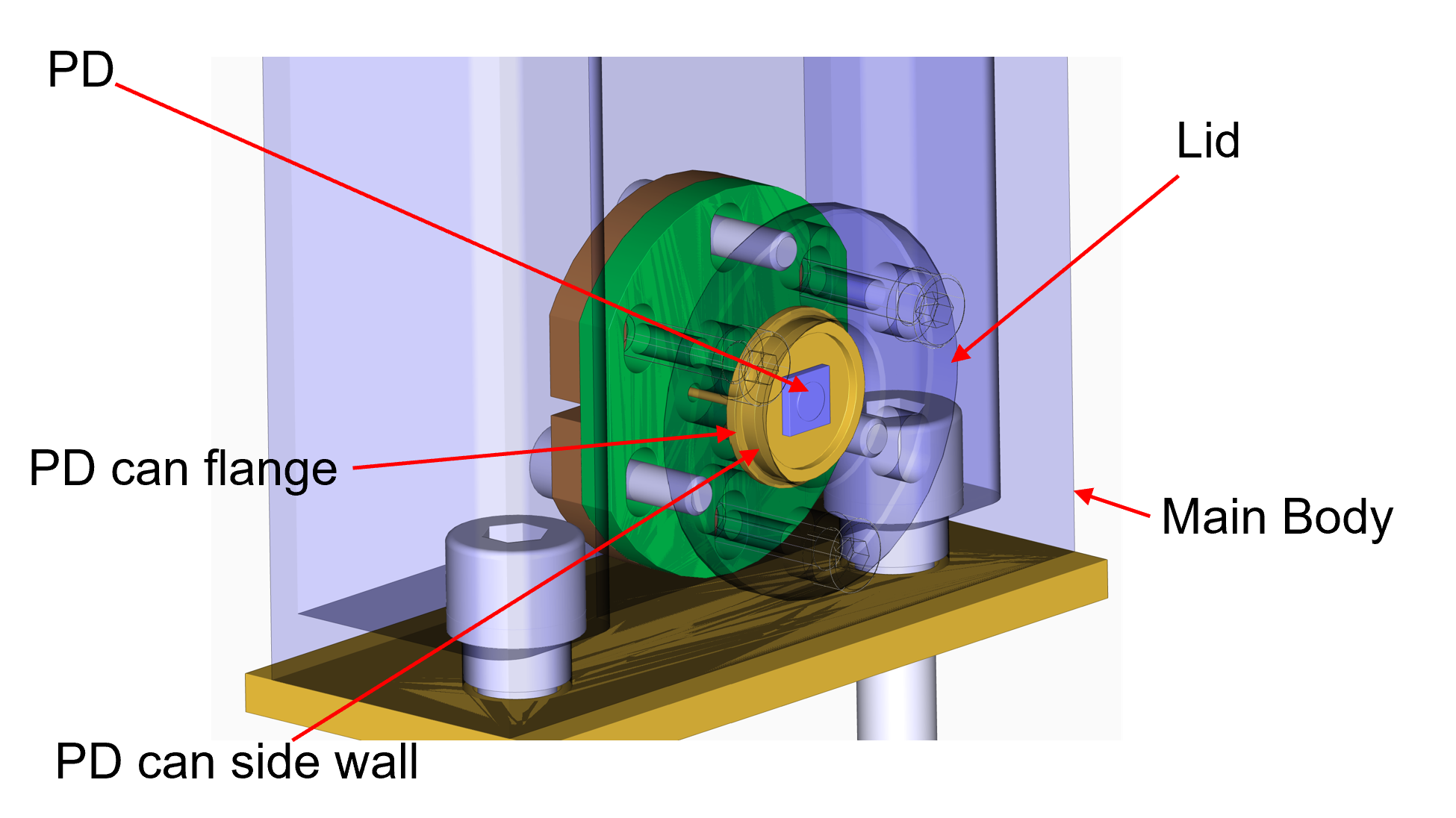

- Opened the can of a PD with a Thorlab tool.

- Put an aluminum foil sheet under the OMC so that small components cannot fall into screw holes.

Actual swap process

The DCPD was reasonably within the reach of my arms. So removing the old PD was easy.

It required some patience to install a new PD but it was possible.

Test of the new PD

We illuminated the PDs with a laser pointer to see the response.

The PDA responded but no response at all from the PDB.

Since PDB responded with the old PD, and changing the PD was the only thing we did after that, we think that the new PD is dead.

This can happen if we apply too much stress during the can opening process.

We will open another PD more gently tomorrow.

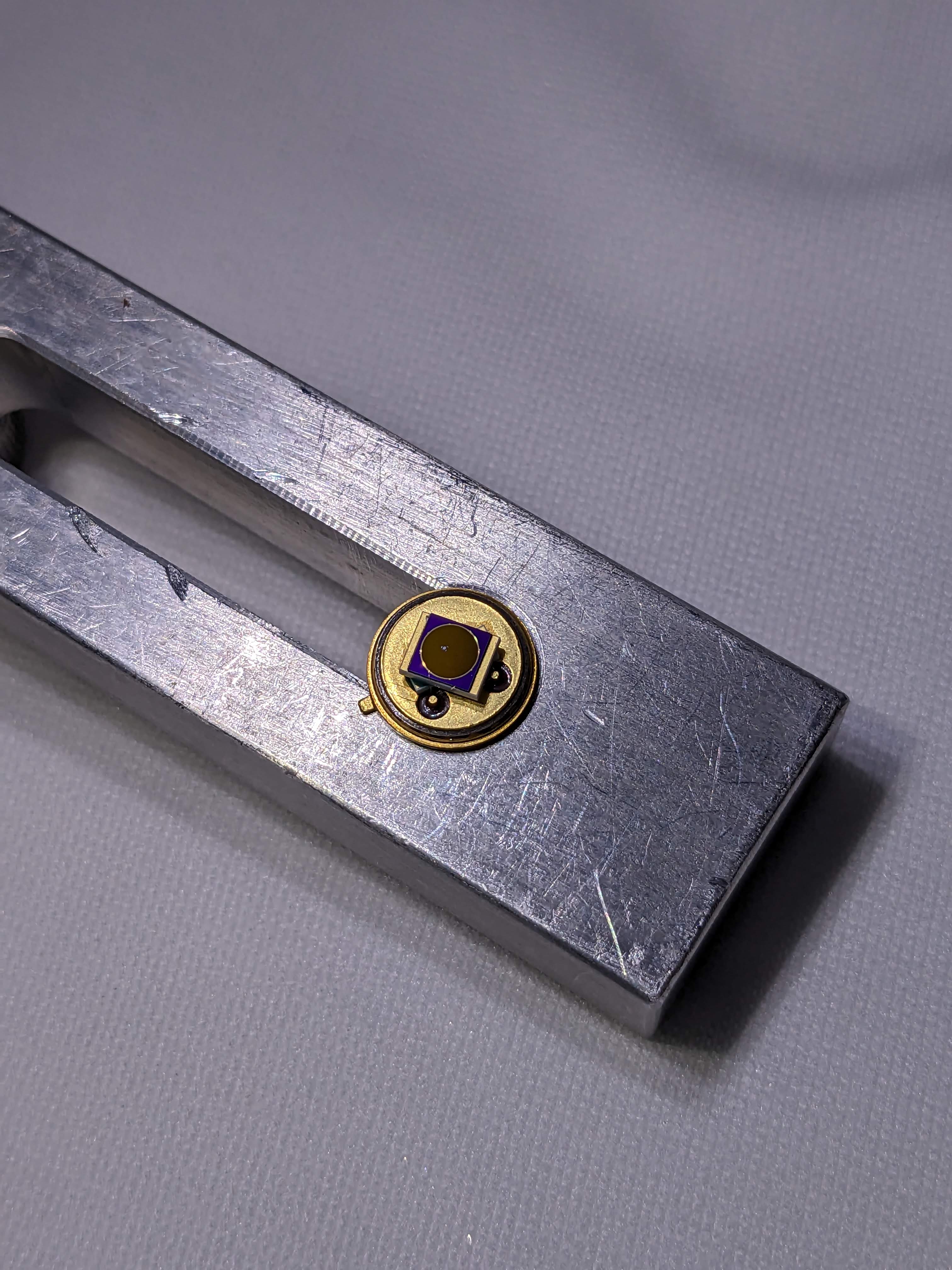

Inspection of the old PD

By looking at the surface of the old PD, we noticed that there is a white spot, possible from burning?

Actually, there is a similar white spot on the PDA too.