With Ohishi-san, Fabian, Enzo, Hirata-san, Yoshioka-kun and Kozu-kun.

Today:

- We set up a 150 mm ruler on a 9.75 mm spacer (an M10 nut) to measure the keystone height. Target was 154.5-9.75 = 144.75 mm.

- The keystone started quite low (17.9 mm from top of the PEEK piece to the top of the PI) in its range and the keystone was also low (143.8 mm; cf 144.75 mm target). This is probably due to Enzo's tests on Friday 9/15. We found 54 mm on the FR gave 144.7 mm on the keystone, and this was about midrange. We put a pair of locknuts on the top of the shaft to prevent the PEEK piece going too high.

- Fabian locked the SF and F0 keystones and measured the BF frequency. On one run of 10 cycles it was 0.443 Hz, and on a second run it was 0.454 Hz.

- Fabian locked the the BF filter and unlocked F0. The F0 frequency on two runs was 0.208 Hz and 0.210 Hz.

- Hirata-san and team brought the LBB damper magnet ring halves into the tank and assembled them on top of the Cu ring, with spacers to stop the magnets being disturbed, clamps to make a sandwich of the rings, and slings to enable lifting.

- We took the lid of the tank off, craned the sandwich of LBB damper rings up to near the top of the tank and hooked the magnet ring to suspend it. (The Cu ring is held underneath by the clamps.) We also installed the end-pieces on the thick security rods to prevent the rings falling in case of a suspension rod failure.

- We investigated the PI yaw stepper motor issue some more. It turns out that the motor is correctly wired, but the odd design of the mechanism it is part of is causing it to jam. The shaft of the motor is threaded and passes through a block with a female thread. The motor is cantilevered at the end of its own shaft (with no other support for the motor or any counterweight at the opposite end at the shaft) so its weight causes the screw to bind up. Supporting the motor with fingertip pressure allows it to run freely, but that is not practical for actual use. We will think about a redesign.

- We checked the height of the F0 yoke. The CAD has the top of the PEEK coil former at 37.5 mm above the recess in the top of the PI and we measured 36 mm. The LVDT reading was already quite near zero for the keystone at nominal, so we decided not to adjust the yoke.

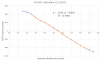

- We did a calibration of the F0 LVDT. See separate klog by Enzo.