Hirata, Takano, Ushiba, Aso

We continued the alignment work around the BS-SR3-SR2 area.

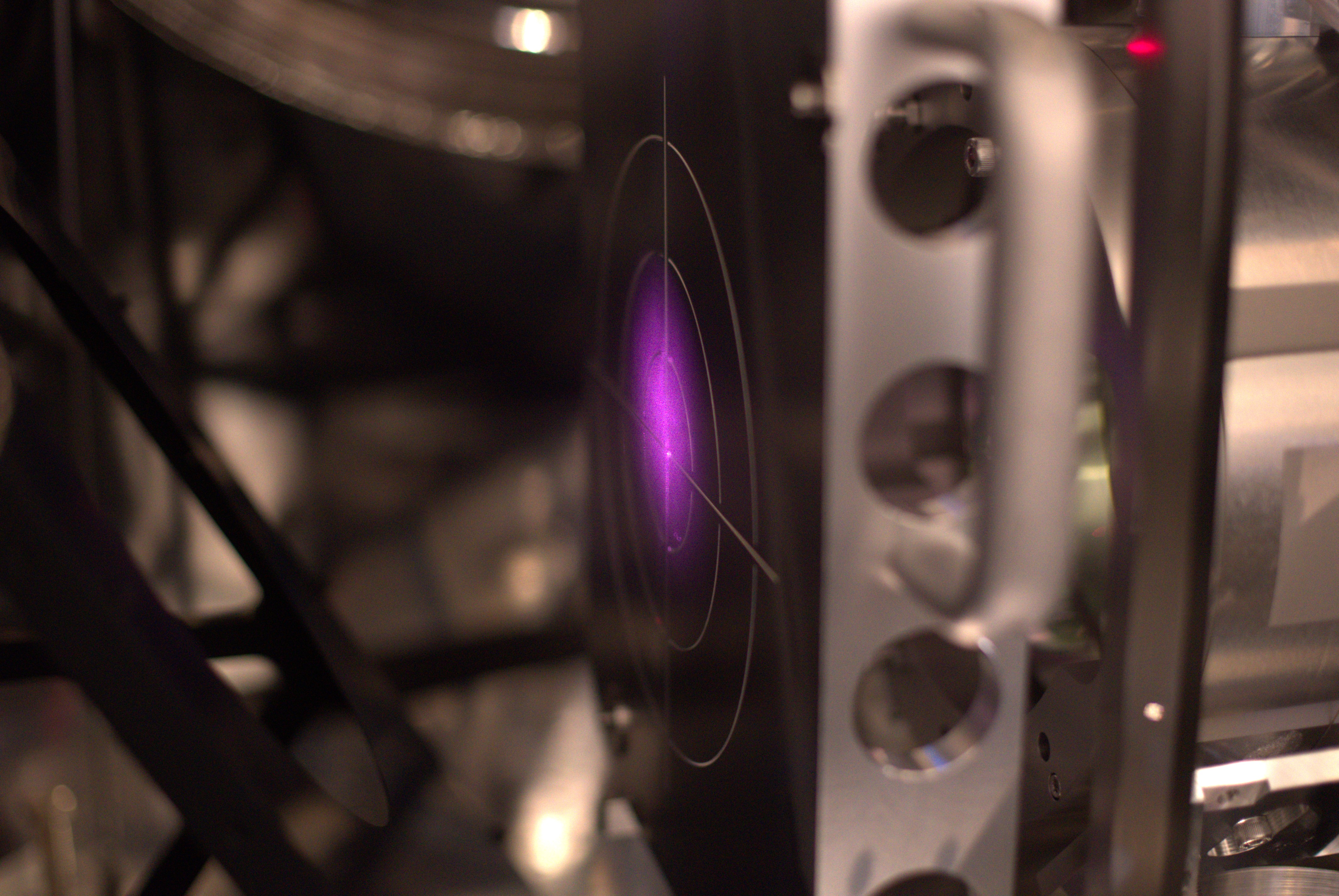

Beam clipping at the BS-IXC gate valve

We took a picture of the BS-IXC GV from the BS chamber, by sticking the IR-camera from the open flange on the -Y side.

Obviously, the beam is clipped on the upper right side.

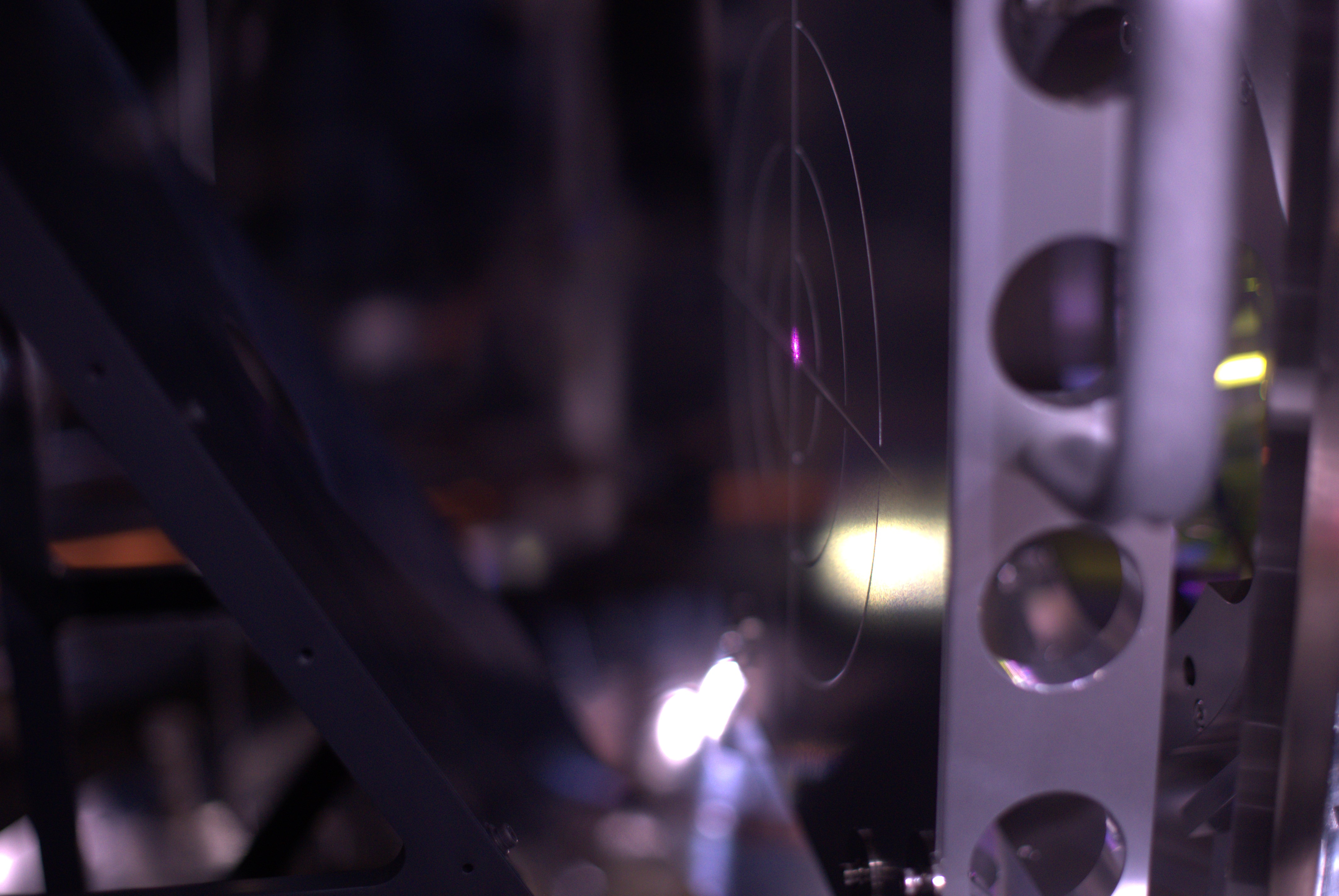

We also checked if there is any sign of clipping on the baffle on the +X side of BS.

No scattered light from the baffle is captured by the camera with 1W output from the IMC.

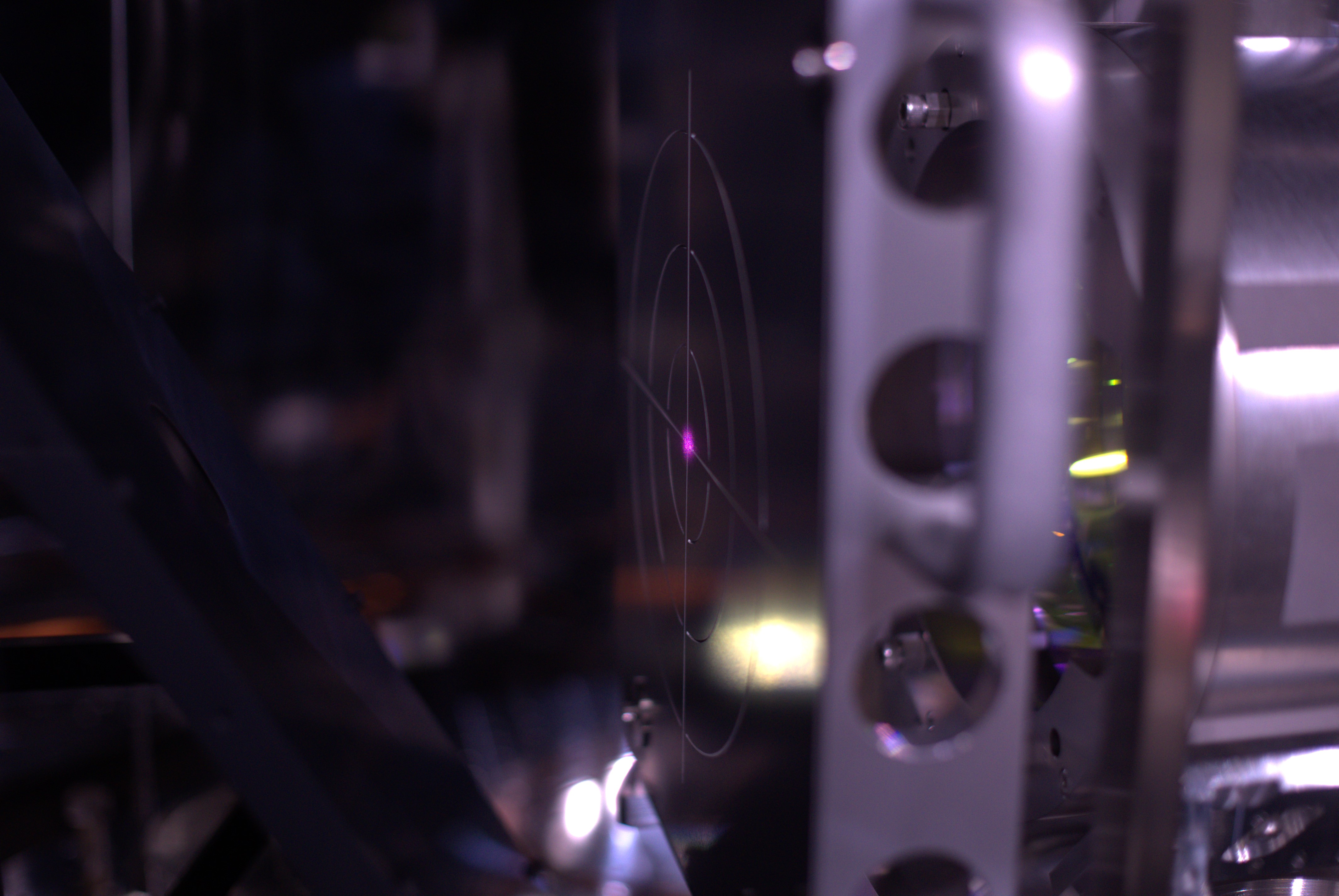

The photo below can be used to assess the height of the beam relative to the BS. It is a bit high, maybe by 2cm?

SR3 beam spot position

Yesterday, we performed ADS alignment after the trans PD clipping was fixed.

The beam spot got closer to the center of the target. Still it is a few cm higher than the center.

Note that the nominal position of the beam from the BS on this target is not at the center, but about 4mm to the right.

Beam spot on SR2

The IR beam spot on SR2 was a bit higher than the center of the target when SR3 suspension is aligned to the sate where Green-Y beam reaches the Y-end.

By pitching the SR3 down by 100urad, we can center the IR beam on the SR2.

Next steps

We think that we cannot change the beam spot position on SR3, because it is basically set by the arm cavity alignment. The beam spots are high everywhere because we set the beam spot on the ITMX high, from the experience of O4a.

Still it is a mystery that the X-arm transmission is only 0.8. The beam clipping on the BS-IXC GV will create a large offset in the ADS error signal for IMMT2 and PR2. We should try to align the arm cavity with ADS on ITMX and ETMX to see if it improves the arm transmission. We may also want to try finesse measurement of X-arm.

For SR2 beam spot, we should move the SR3 to center the beam on SR2 while adjusting the green injection path from SR2 to keep the beam reaching the Y-end.