Marc, Yuhang, Michael, Aso

Summary

Today, we started the cleaning process of ETMY.

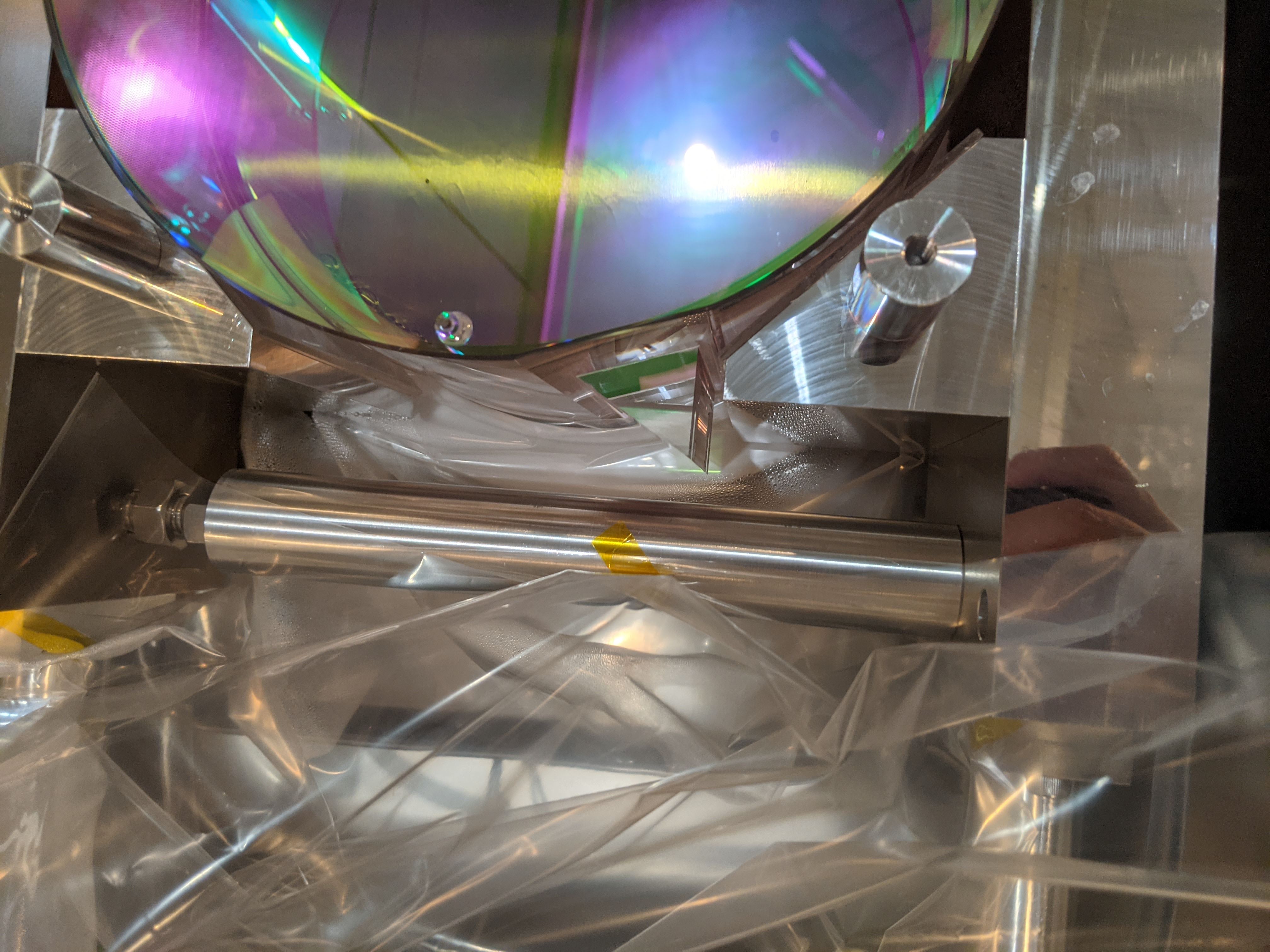

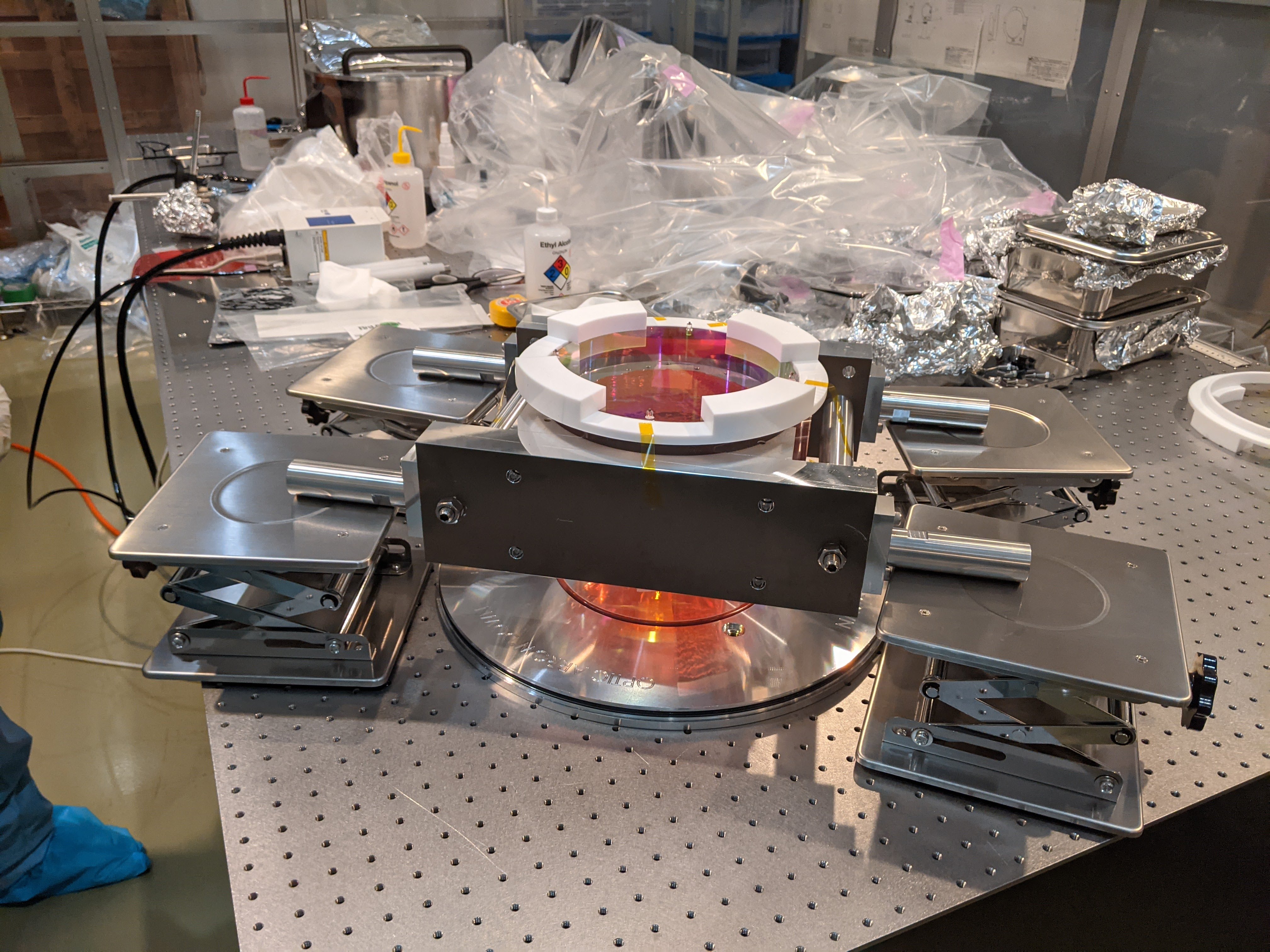

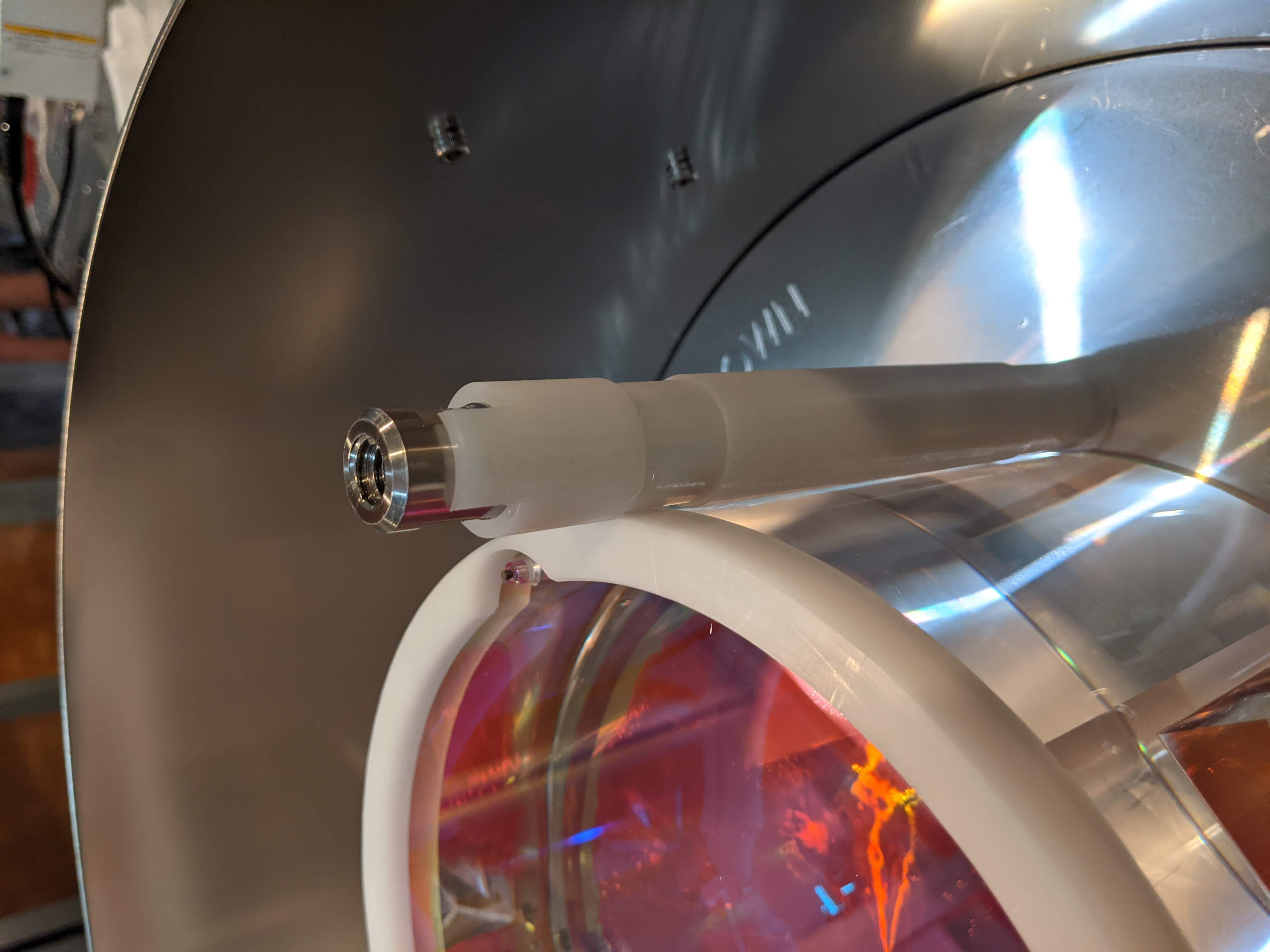

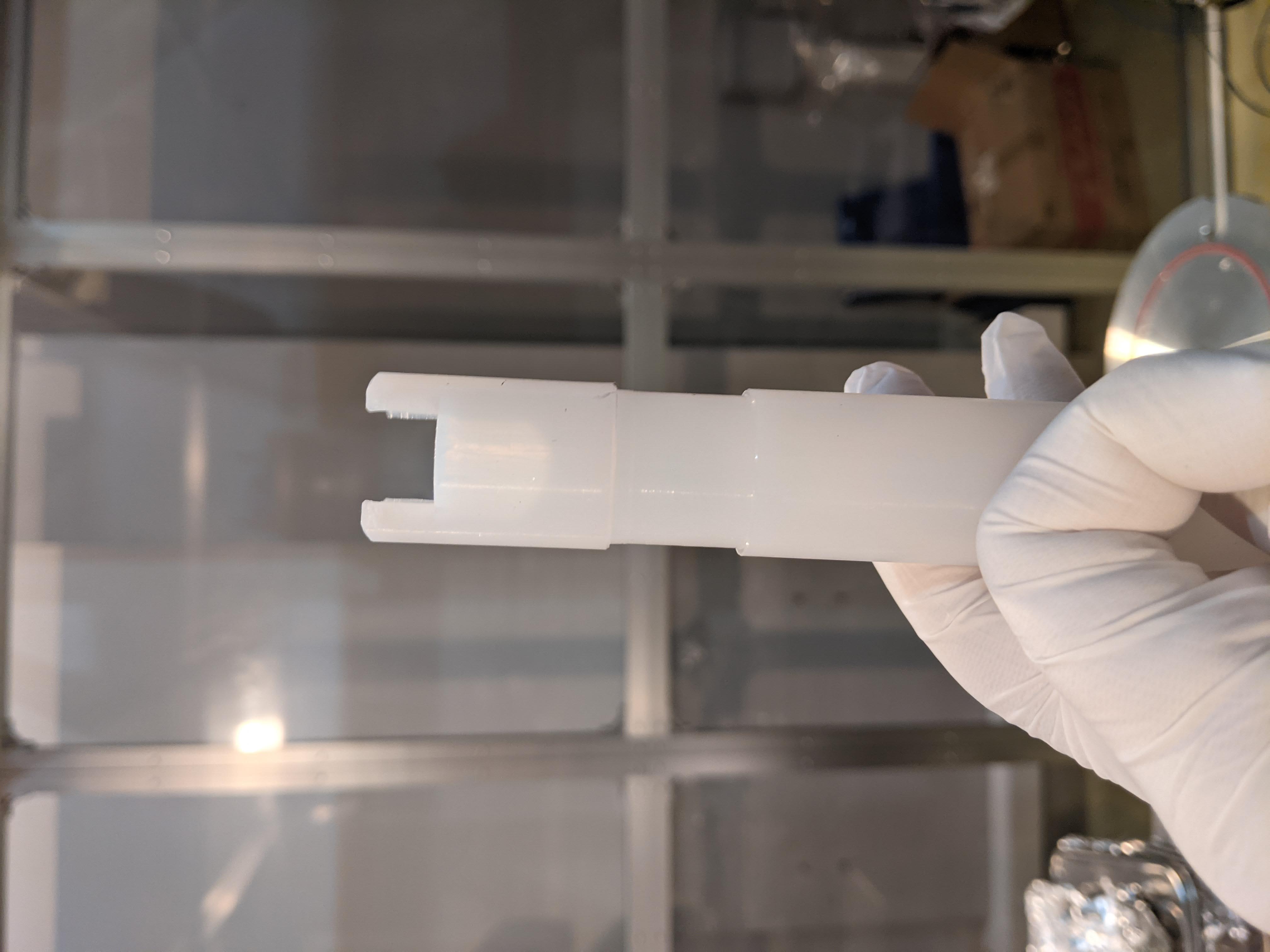

First, we successfully assembled the newly designed handling jig and mounted it on the mirror.

Using the jig, we held the mirror upright and inspected the HR and AR surfaces closely.

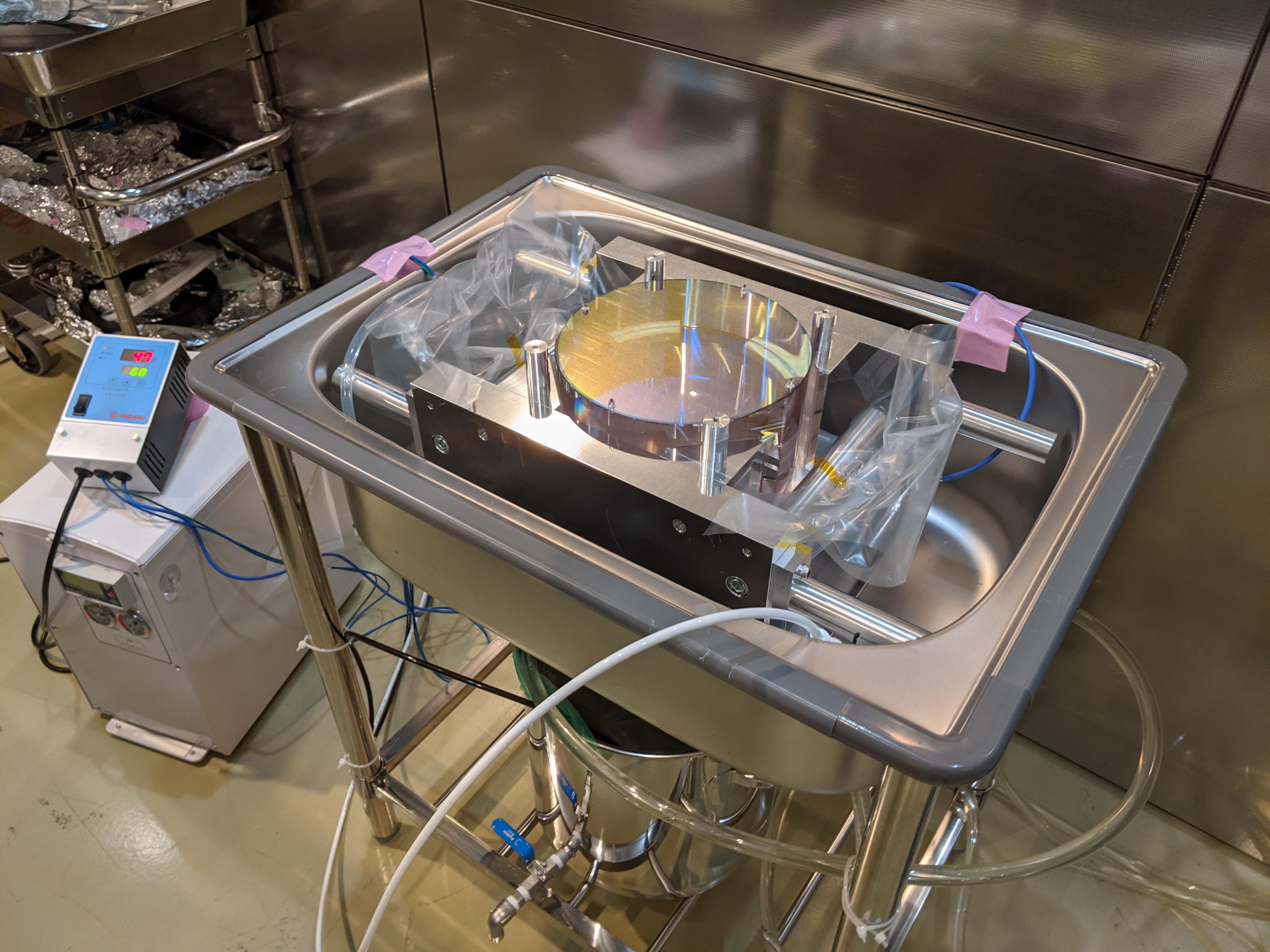

After the inspection, we put the mirror in the water bath and started the ultra-pure water circulation.

We will continue the cleaning process until the morning of Thursday.

Surface inspection

You can find the photos here (all the mirror photos are of the HR surface):

https://photos.app.goo.gl/Mk2iUe2iTTreHr6BA

(some of the important photos are directly attached to this report)

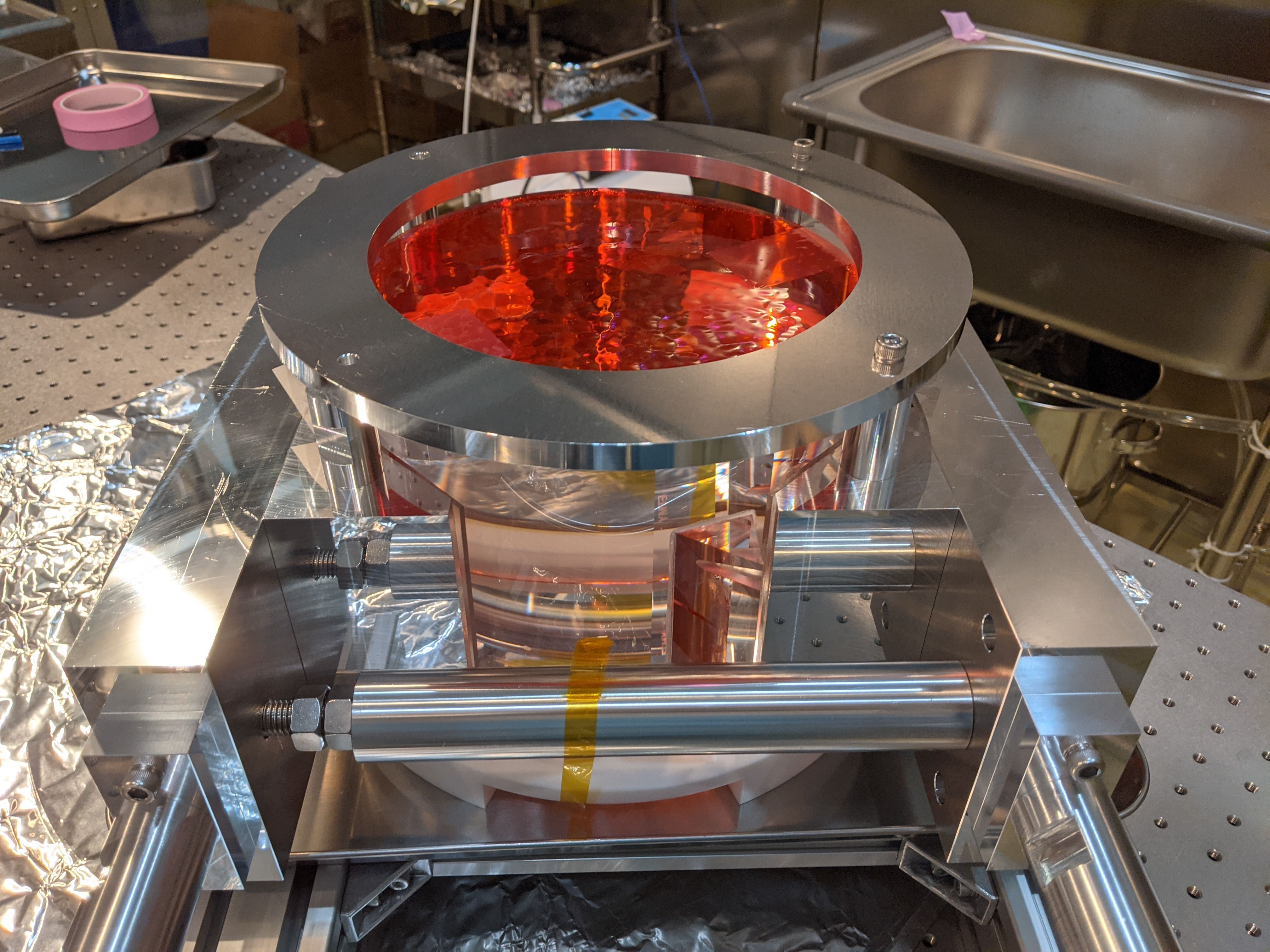

We found many stains on the HR surface.

Scattered raindrop like spots near the bottom of the mirror look similar to the stains on the contaminated viewports.

There are other stains which do not look like the same origin as the viewport stains.

Because of the splash like nature of the contamination this time, spatially extended faint stains are probably from different origins.

There is a big stain near the center of the mirror, which also do not look like the same origin as the VP stains.

On the AR surface (we did not take any picture of AR this time), we did not find any extended stain in the central area (within 15cm diameter or so). Only tiny spots are present there. We think they are dusts.

We did find some large stains near the edge of the AR surface. Some of the stains look like the stains of the VP. These stains are sufficiently near the edge that I am comfortable to wipe them, or even leave them as is.