Simon, Akutsu on 20180227

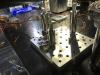

Replaced a tentative breadboard, which has supported photosensors and a coil, and a burndy connector, to a small but vacuum compatible one (Fig 1) on the cryostat breadboard. Then again install photosensors on the small breadboard (Fig 2-7). And we set the coil stand on the cryostat breadboard directly, as the new one was small as already described (Fig 8 and 9). So did the burndy connector stand. Then we checked the sensors' singals, and adjusted the hieght of the coil support so that the distance from the manget attached to the WAB and the coil becomes nice. And with those setting, we measured the damping waveforms of the WAB suspension, and the detail will be reported later.

In Fig. 9 the upper left's black is not meaning loss of data, but just the baffle.

The coil was located with respect to the magnet so that the actuator will excert force to the WAB in as much directions; note that the purpose of the actuator is just to make an attack impulse for measuring the damping ratio of this suspension system.

By the way, the last night I and Takahashi-san washed several parts for vacuum use including the small breadboard, and then left them on a desk wiyj a cover for expecting natural dry, but this morning we found the breadboard (unanodized aluminum) got rust as the outer shapes of stainless parts just left on the breadboard. This is actually just another example of "eat" or corroding of metals (google and find! Al vs SUS). I polished the surface by a rough waterproof abrasive cloth, and washed again... be careful.